Forklift steering axle and forklift

A technology of forklift steering axle and steering rack, applied in steering mechanism, mechanical steering gear, fluid steering mechanism, etc., can solve the problems of large energy loss, low control accuracy, steering wheel center drift, etc., to avoid energy waste , The effect of high transmission precision and high steering precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

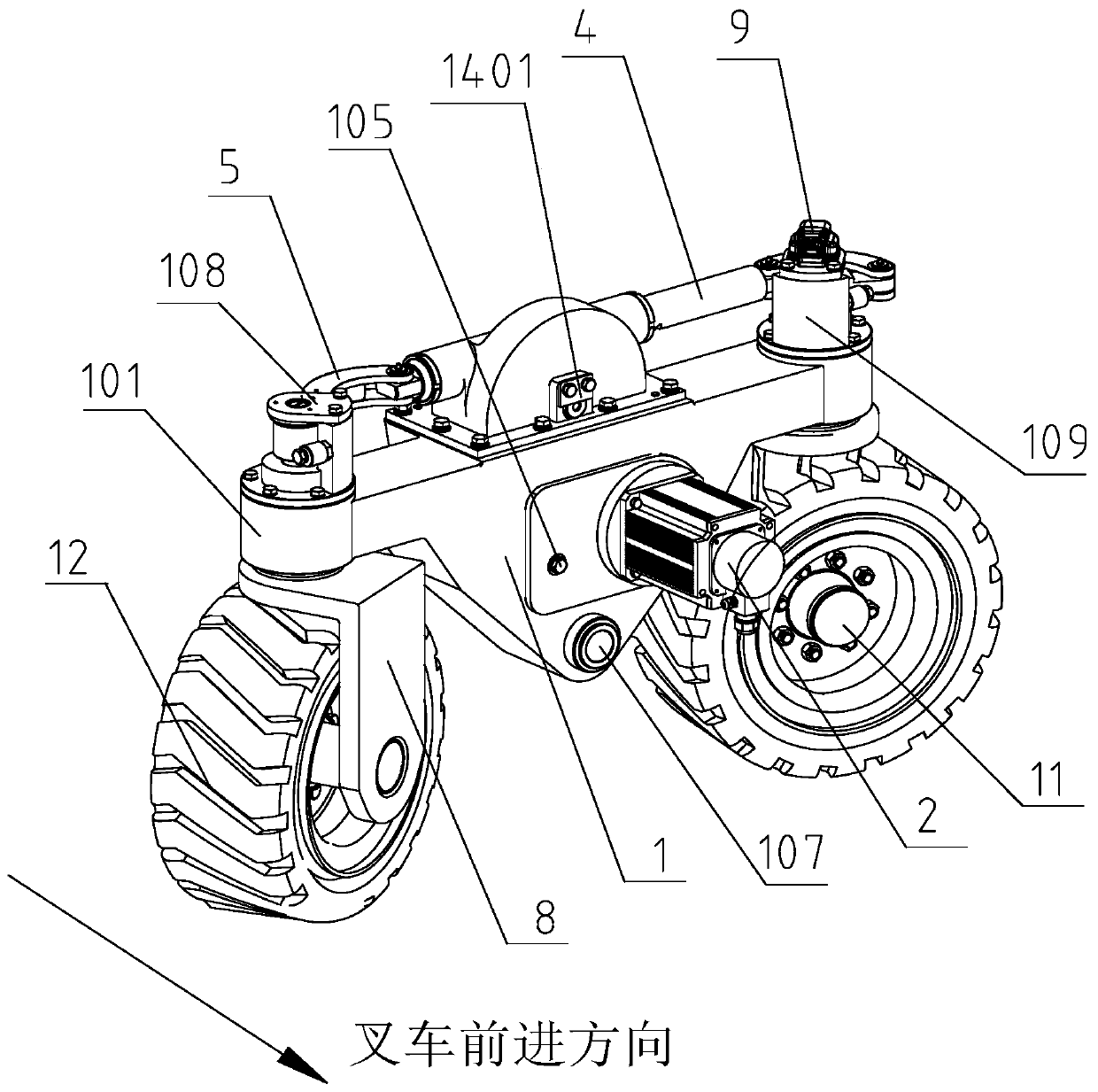

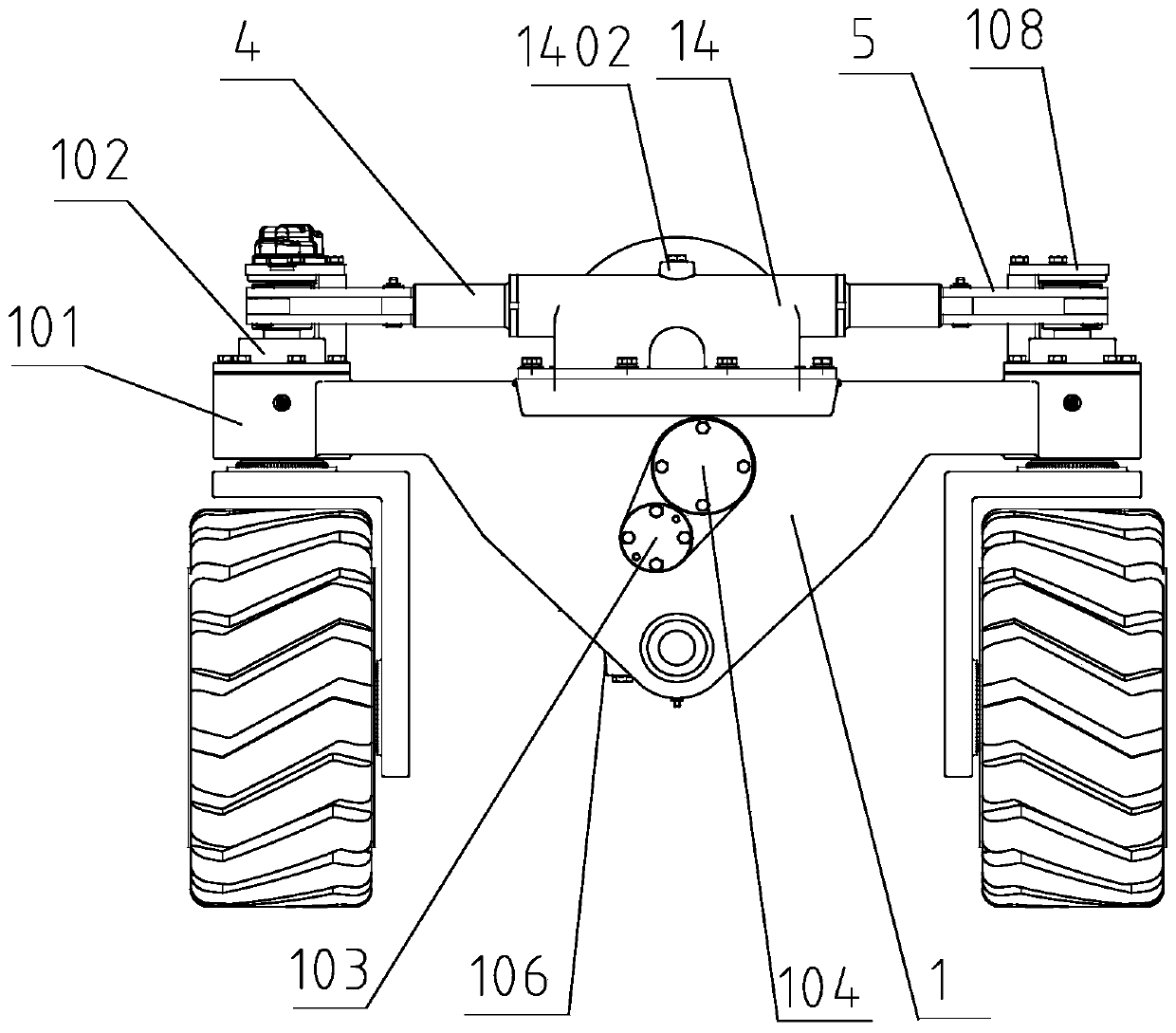

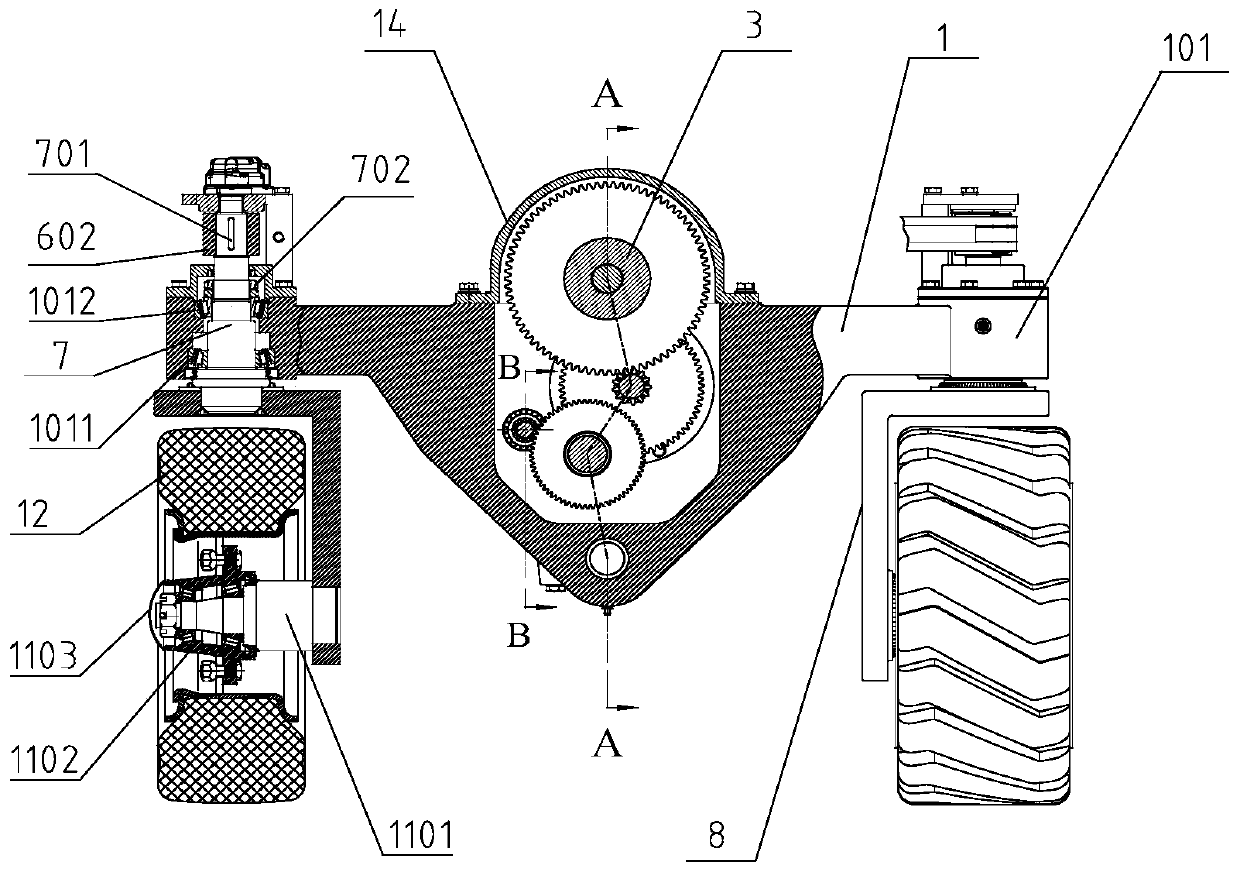

[0060] An embodiment of the present disclosure provides a forklift steering axle, such as Figure 1 to Figure 5 As shown, the forklift steering axle includes a bridge body 1, a motor 2, a steering gear 3, a steering rack 4, a left steering mechanism and a right steering mechanism. Specifically, the steering gear 3 meshes with the steering rack 4, and the steering rack 4 The two ends are respectively connected with the left steering mechanism and the right steering mechanism, and the left steering mechanism and the right steering mechanism are fixedly connected with the hub 11 of the wheel respectively, and the motor 2 is used to drive the steering gear 3 to r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap